It is important to know that these types of chambers have a higher chemical resistance than other types. Therefore, it works well with alcohol, thinners, and acetones, to mention a few. Furthermore, they have the capacity to operate in wide temperature ranges; you may have to ask the manufacturer or dealer about expanding the temperature ranges to suit your specific needs.

How Does It Work?

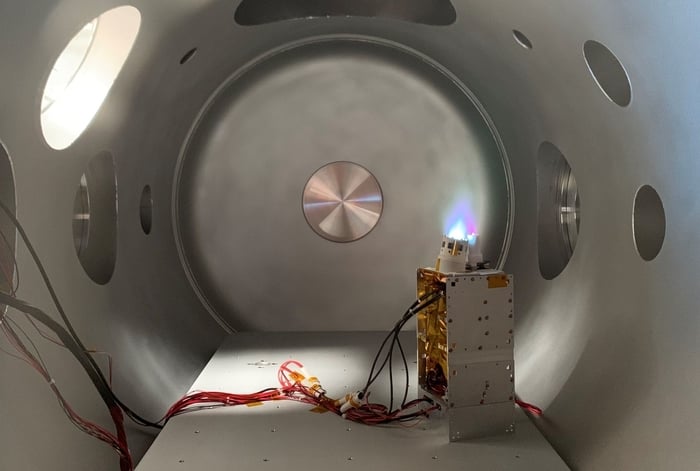

A stainless steel vacuum chamber operates in much the same way as the standard one. It is an ultra high vacuum chamber and works by removing gas and air out of a chamber or vessel using a pump. The action creates a vacuum in the vessel, where there is no matter left in it. The process is not the same as sucking the air out; the device does not remove gas or air by sucking.

To create a vacuum means leaving no atom or molecule in space and a molecule can be removed only when there are random collisions. Since sucking does not create these collisions, the act cannot create a vacuum. Therefore, the device makes a vacuum by creating random collisions of molecules as they enter the pump.

The process has the likelihood of building pressure, but you can control it. Consider metering gas into the vessel or chamber when you are pumping or limit its removal per time. And if you have a pressure point you want to maintain, you may have to cut the leak-up rate by continuing the pumping process at a specific level.

Uses:

It is true that stainless steel chambers are some of the most advanced because of their extremely high chemical resistance. But they are also good for the standard vacuum chamber purposes. Some of the specific purposes for the manufacture of these types are:

- Genetic engineering

- Altitude simulation

- Quality control

- Scientific experiments

- Hi-pot discharge testing

- Freeze-drying

- Industrial uses

- Package integrity testing

- Laboratory research

The following are general uses of a vacuum chamber, including the stainless steel type:

- Drying Materials

When the pressure in a vacuum chamber drops, it affects fluids’ vapor pressure and changes the fluid from liquid to gas. This process is what dries liquid from materials stored in it, so you can use it to remove water from items or fluids in foods.

-

Storage

If you have items that show sensitivity to moisture or other conditions in the atmosphere, you can store them in this device to prevent damage. However, it may not be accessible to everyone, so this option is pretty limited.

-

Specialized Treatment

Manufacturers can use the device for giving materials the plasma treatment. That way, the process makes it easier to etch, activate, deposit, and clean the materials for manufacture. In other words, materials can be evenly treated. Click this link https://www.thierry-corp.com/ to learn more about special applications.

-

Simulation in High Altitudes

The pressure of the air lowers the higher you go in the air. But when you control the air in a vacuum chamber, you are free to create certain conditions at higher altitudes. It makes things easier when it comes to simulations in high altitudes so that products and materials to be used in the aeronautics and aerospace industry can be tested.

-

Odor Removal

Typically, gases and vapors from materials or items create odors. But when the air pressure drops, there is a faster emission of the vapor or gas causing the odor. That way, there is little left to cause an odor. You can achieve the low pressure needed to achieve the loss of odor if you use a vacuum chamber.

Safety Guidelines

It is crucial to have the required training to operate a vacuum chamber. Not everyone should touch or use it; it is not a device that commonly lies around. But if you have to work with it, ensure you are not under any alcoholic influence and you know the operation steps. Read this article for more information on safety steps.

Always use it in an organized environment, free of any obstacles, and safe to work in, especially if you are not alone. The area must be properly ventilated; it is not safe to use it in a closely confined space with poor ventilation. The surface on which you put it must be flat and there must be no child or pet in the vicinity.

Protect yourself; wear a shield over your face, gloves, goggles, a respirator, and protective clothing. Do not directly look into or stand next to the chamber without proper protection. Also, ensure there is no damage to the device before usage; check for dents or cracks. Return it to the manufacturer if you do.

Monitor the device all the time; never take your eyes away from it. If you are assembling it, point all its components away from your body. The same applies if you are disassembling it. In addition, keep from moving it while it is in full or partial operation. Doing so may damage the device or structure in which you work.

Conclusion

Vacuum chambers have their uses, and stainless steel ones seem to have specialized uses. If you are looking to buy one, it is crucial to find a good manufacturer, proven reliable in that area. Also, follow the operating instructions to prevent loss of property or injury to self.

Read more blog: Best vacuum under 200 reviews

Leave a Reply